+91-9814229208

info@amitbroaches.in

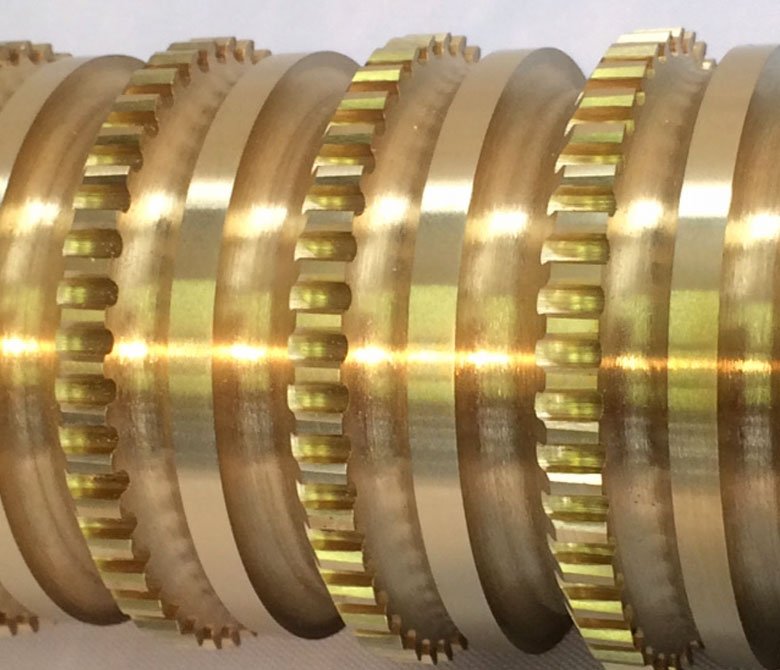

Internal slots, grooves, and interspaces in components like gears, shafts, couplings, and machine parts require high precision machining. Interspace broaches are specifically designed to meet these requirements, providing accurate, smooth, and repeatable internal cuts with minimal post-processing.

At Amit Broaches, we manufacture high-quality interspace broaches used in automotive, aerospace, defense, and industrial machinery, ensuring maximum tool life, performance, and precision.

An interspace broach is a multi-tooth cutting tool designed to create precise internal grooves, slots, and spaces inside bores. Unlike keyway or spline broaches, interspace broaches are optimized for:

Wider slot cutting

Deep grooves

Complex internal profiles

How Interspace Broaching Works

The broach is pushed or pulled through a pre-drilled bore. Each successive tooth removes a small amount of material until the full slot depth and width are achieved

This method ensures:

- Uniform groove width

- Accurate depth

- Smooth surface finish

- Minimal tool deflection

Types of Interspace Broaches

At Amit Broaches, we manufacture multiple types of interspace broaches based on application and groove requirements:

1. Standard Interspace Broaches

Used for general internal groove machining in gears, pulleys, and couplings.

2. Custom Groove Broaches

Engineered according to OEM drawings or special slot geometries.

3. Multi-step Interspace Broaches

Designed to cut multiple grooves in a single pass, saving time and improving productivity.

4. Internal Pulley & Slot Broaches

Specialized broaches for pulley keyways and industrial machinery.

5. HSS & Carbide Interspace Broaches

For soft to hardened materials, with optional coatings for extended tool life.

Materials Used in Interspace Broaches

The material selection is critical to performance and durability:

1. High-Speed Steel (HSS)

Cost-effective

Excellent wear resistance

Suitable for general-purpose broaching

2. Powder Metallurgy (PM) Steel

Superior hardness and longevity

High-volume industrial applications

3. Carbide-Tipped Broaches

Cutting hardened materials

High-precision applications

Coatings

TiN, TiCN, TiAlN

Reduce friction and heat

Enhance tool life

Manufacturing Process of Interspace Broaches

Precision manufacturing is key to high-quality broaches. Our process includes:

Material Selection – Only certified HSS or PM steel.

CNC Machining – Precise tooth geometry and taper.

Heat Treatment – Ensures hardness and wear resistance.

Grinding & Profiling – Achieves exact slot dimensions.

Coating (Optional) – Improves durability and reduces friction.

Quality Inspection – Tooth profile, width, depth, straightness, and surface finish.

This ensures consistent, reliable performance for industrial applications.

Applications of Interspace Broaches

Interspace broaches are widely used in industries requiring precise internal slot and groove machining:

1. Automotive

Gear grooves

Pulley slots

Shaft interspaces

2. Aerospace

Landing gear components

Precision machinery parts

Engine housings

3. Heavy Machinery

Hydraulic cylinders

Pulleys and couplings

Industrial gear assemblies

4. Defense

Weapon and vehicle components with precise internal slots

5. Industrial Equipment

Bearings, rollers, and bushings

Custom machinery requiring internal groove profiles

Advantages of Using Interspace Broaches

Interspace broaching offers significant benefits:

- Single-pass machining for grooves and slots

- High accuracy and repeatable dimensions

- Superior surface finish

- Suitable for high-volume production

- Minimal operator skill required

- Long tool life with proper care

- Capable of machining soft and hardened materials

How to Select the Right Interspace Broach

Choosing the right interspace broach depends on:

Slot Width & Depth – Determines broach size and type.

Material of Workpiece – HSS, PM steel, or carbide required.

Bore Diameter – Must match broach guide.

Production Volume – Coated broaches recommended for high-volume operations.

Machine Type – Push or pull broach machines affect broach selection.

Amit Broaches’ engineering team assists in selecting the ideal tool based on application and drawings.

Maintenance & Re-sharpening

Proper maintenance prolongs broach life:

Inspect teeth regularly

Re-sharpen when cutting efficiency drops

Use adequate coolant

Store in protective cases

Avoid excessive force during broaching

We provide professional re-sharpening and reconditioning services for all interspace broaches.

Why Choose Amit Broaches for Interspace Broaches?

ISO-certified manufacturing

CNC and precision grinding capabilities

Custom designs based on OEM drawings

Premium HSS, PM steel, and carbide broaches

100% inspection for accuracy and finish

Competitive pricing with reliable delivery

Expert technical support

Industries trust Amit Broaches for durable, precise, and high-performance interspace broaches.

Conclusion

Interspace broaches are essential tools for producing precise internal grooves and slots in shafts, gears, and industrial machinery. Their accuracy, efficiency, and durability make them indispensable in automotive, aerospace, and heavy machinery industries.

At Amit Broaches, we manufacture high-quality interspace broaches tailored to customer requirements, ensuring superior performance, long life, and precise machining results.

Looking for premium Interspace Broaches?

Call: +91-9814229208

Email: info@amitbroaches.in

Website: www.amitbroaches.in

Location: Punjab, India